expenses for drilling water wells by manufacturing company

Although the process of drilling a water well can be costly for a manufacturing company, it still holds great promise for cost reduction and enhanced productivity. This article will cover the financial implications that come with drilling a water well, as well as provide valuable advice on how to mitigate such costs.

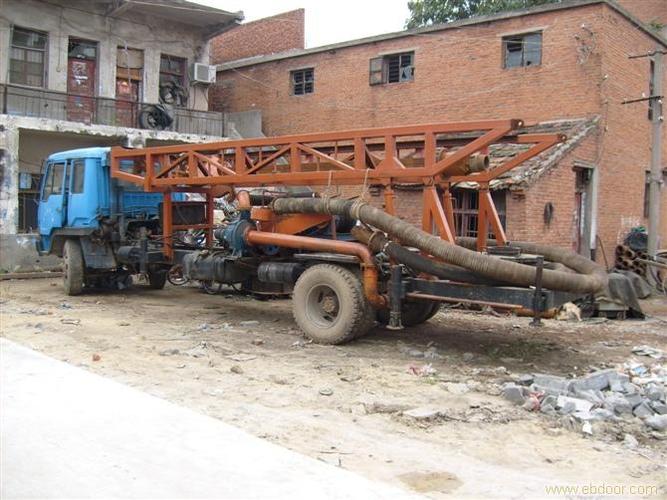

Constructing a water well has its expenses, starting with the bill for the necessary tools. Such materials may include a drill, drill bit, and additional components which adapt according to what is needed for the task at hand. The price tag may skyrocket depending on well depth, existing composition of the drilled land (be it soil or rock), and later-stage apparatus like pipes, tanks, and pumps that may be required. A larger, more powerful drill may be necessary when targeting deeper grounds, with a consequent jump in the total bill. Overall, the price of equipment contributes significantly to the final cost.

Labor costs may prove as an expensive factor when it comes to drilling a water well. The hours of laborious work that may go into this process is contingent on the complexity or size of the well, with some jobs potentially taking days or weeks. It is essential to consider labor in the budgeting of a drilling project, as the price of manpower can differ depending on the surface it is drilling through—hard rock and soil being generally more costly than softer terrain.

The next factor to consider when drilling a well is materials: that is, gravel, sand, steel pipe, and any other materials necessary for the specific type of well. As such, it’s essential to account for the cost of these materials when allocating a budget. Moreover, they may need to be obtained from some external source, thus further adding to the overall expense.

From state to state, local governments can levy different forms of expense for drilling a well. Generally speaking, these payments correlate in price to the scale of the project and the local rules. An inescapable requirement in most cases is a permit or license; the charge for obtaining this will depend on a number of factors.

To avoid the potential consequences of an unsafe water supply, testing is an essential part of the process. Thus, the fifth expenditure involves bearing the expense of trial runs to assess the quality of the well after it has been drilled. Although assessments can be costly, they remain mandatory in order to guarantee a potable liquid source.

Investing in water wells can be costly for manufacturers, but the potential long-term advantages of having a dependable source of water can make the pricetag meaningful. To minimize cost, stakeholders should account for all expenditures tied to the drilling effort, from materials and equipment to licenses and permits. Practically, firms can also cut down on labor costs needed for the excavation by strategically treating employees as multi-faceted and teaching them how to perform related tasks. When done correctly, this smart financial approach can not only pad the bottom line but also promote more efficient processes.

As the expense of potable water continues to skyrocket, manufacturing companies are being hit with hefty bills when opting to drill water wells. To provide a better understanding of the costs associated, this article will explore drilling expenses for water wells and detail easy tips to lessen the burden on manufacturers.

The outlay for establishing a water well to aid production operations is determined by several components, including the kind of well, its depth, and the nature of the location. These wells can extend from shallow to incredibly deep depths – some spanning as far as thousands of feet beneath the surface – while the amount of expenditure required is contingent on features of the site, from its level of complexity to the type and volume of labor needed. The equipment chosen is also a factor in the amount spent.

The price for drilling a well to supply water to manufacturing companies varies significantly, and could amount to anything from thousands to tens of thousands of dollars. This is usually determined by the estimated cost of the drilling itself, as well as other associated expenses including equipment, labor, etc. It should be highlighted however that if the site is particularly challenging or the work required is more intensive, then the expense for drilling a water well for these businesses can end up being substantially more.

If you’re aiming to cut costs when drilling a water well for a manufacturing company, consider working with a specialist in the field. Professional drilling companies that specialize in water wells for manufacturing can provide the essential tools and experience to complete the job quickly and economically.

To secure the best deals on well-drilling services in the area, it is important to investigate local costs associated with this practice. This will allow businesses to scope out potential savings made through competitive bidding and negotiation. Additionally, it can help to recognize which companies offer the most economical prices when it comes to drilling wells for manufacturing purposes.

Manufacturing companies must account for the extended monetary contribution required on their capital when researching drilling water wells. Not only is there a fee associated with upkeep and restoration of the well, but one must contemplate the sustained cost of the collected liquid. Over time, this expenditure can amass to a grand amount, influencing the estimated budget of the entire venture.

Manufacturing businesses can significantly reduce the expense associated with drilling a water well by researching the local market, enlisting a professional drilling firm, and being conscious of long-term costs. Careful preparation can bring significant savings and ensure that the well works dependably and cost-effectively. Taking the time to properly plan prior to drilling a water well is essential for economical outcomes.

-

KQZ200D Shelf Drill Water Well Drilling RigView More >

KQZ200D Shelf Drill Water Well Drilling RigView More > -

FYL200 Water Well Drilling RigView More >

FYL200 Water Well Drilling RigView More > -

FY180 Water Well Drilling RigView More >

FY180 Water Well Drilling RigView More > -

FY380 water well drilling rigView More >

FY380 water well drilling rigView More > -

Electric 7000WView More >

Electric 7000WView More > -

FYX180 Water Well Drilling RigView More >

FYX180 Water Well Drilling RigView More > -

Diesel 22HP180View More >

Diesel 22HP180View More > -

FY350 Water Well Drilling RigView More >

FY350 Water Well Drilling RigView More > -

Diesel 12HP180View More >

Diesel 12HP180View More >

Warning: Use of undefined constant rand - assumed 'rand' (this will throw an Error in a future version of PHP) in /www/wwwroot/www.sunritawdr.com/wp-content/themes/msk5/single.php on line 65

-

affordable water well service & drilling

-

water well drilling cost in indiana

-

residential water well drilling installation crown point in

-

drilling water wells in mexico

-

water well drilling jobs in texas

-

average cost to drill a water well in louisiana

-

water well drilling machines

-

water well drilling resume sample

Warning: Use of undefined constant rand - assumed 'rand' (this will throw an Error in a future version of PHP) in /www/wwwroot/www.sunritawdr.com/wp-content/themes/msk5/single.php on line 123